Electrical Safety: Top 10 Tips Every Tech Should Know

When your team is working in the field throughout the day, it’s hard to know if each job site your techs enter is a safe...

Mar 12, 2024

# of Minutes to Read

When your team is working in the field throughout the day, it’s hard to know if each job site your techs enter is a safe working environment. Especially in electrical contracting, each job has its own set of hazards that become increasingly dangerous when electrical tools and equipment are brought into the mix–which is why we recommend setting electrical safety standards with your team.

To help reduce the risk of potential hazards, it’s important for you and your team to stay up-to-date on the industry’s top electrical safety standards. Below, we’ve provided ten best practices for electrical safety at every job site.

- 1. Always keep yourself insulated when working with live circuits. When working with electrical currents, keep one hand at your side and away from conductive materials to reduce the risk of current passing through your body.

- 2. Keep your workspace clean to reduce potential hazards. While working, it’s important to keep your workspace clean to reduce potential shock hazards and risk of accidents for those working around you.

- 3. Wear electrically safe protective clothing. Always wear protective gear and clothing, like shatter-proof eyewear and non-conductive work boots, while on the job site, no matter if you are working with live electrical circuits or not.

- 4. Be cautious of weather-related hazards when working outside. For outdoor jobs, bad weather and condensation can create dangerous work environments. Be aware of your surroundings and make sure electrical tools and equipment are properly stowed at all times. Check out our blog post on electrical safety in winter for more tips related to cold weather.

- 5. Always discard and replace damaged equipment. Tools and equipment items that are noticeably damaged or begin to produce small sparks while working should be tossed and replaced immediately.

- 6.Use a non-contact voltage tester before working with outlets and conductors. After circuits and power panels have been turned off, it’s important to double-check the voltage to ensure no live wires are remaining on.

- 7. Locate any underground circuits, boxes and breakers. Before digging or working underground, remember to locate any electrical circuits, boxes and/or breakers and ensure no trips have occurred to reduce the risk of overload and electrical fire.

- 8. Use ground fault circuit interrupters (GFCI). To ensure your working environment is safe, always use a GFCI and reduce any imbalances between outgoing and incoming currents.

- 9. Remove any metal accessories and tools before working with electrical equipment. Ladders, rulers, metallic pens and pencils, and even rings and watchbands are extremely conductive. Remember to remove these, and put them in a safe place out of harm’s reach.

- 10. Store electrical tools and equipment safely, away from potential hazards. Before leaving a job site, make sure all electrical tools and equipment are unplugged, and properly stored away from areas susceptible to extreme cold and condensation.

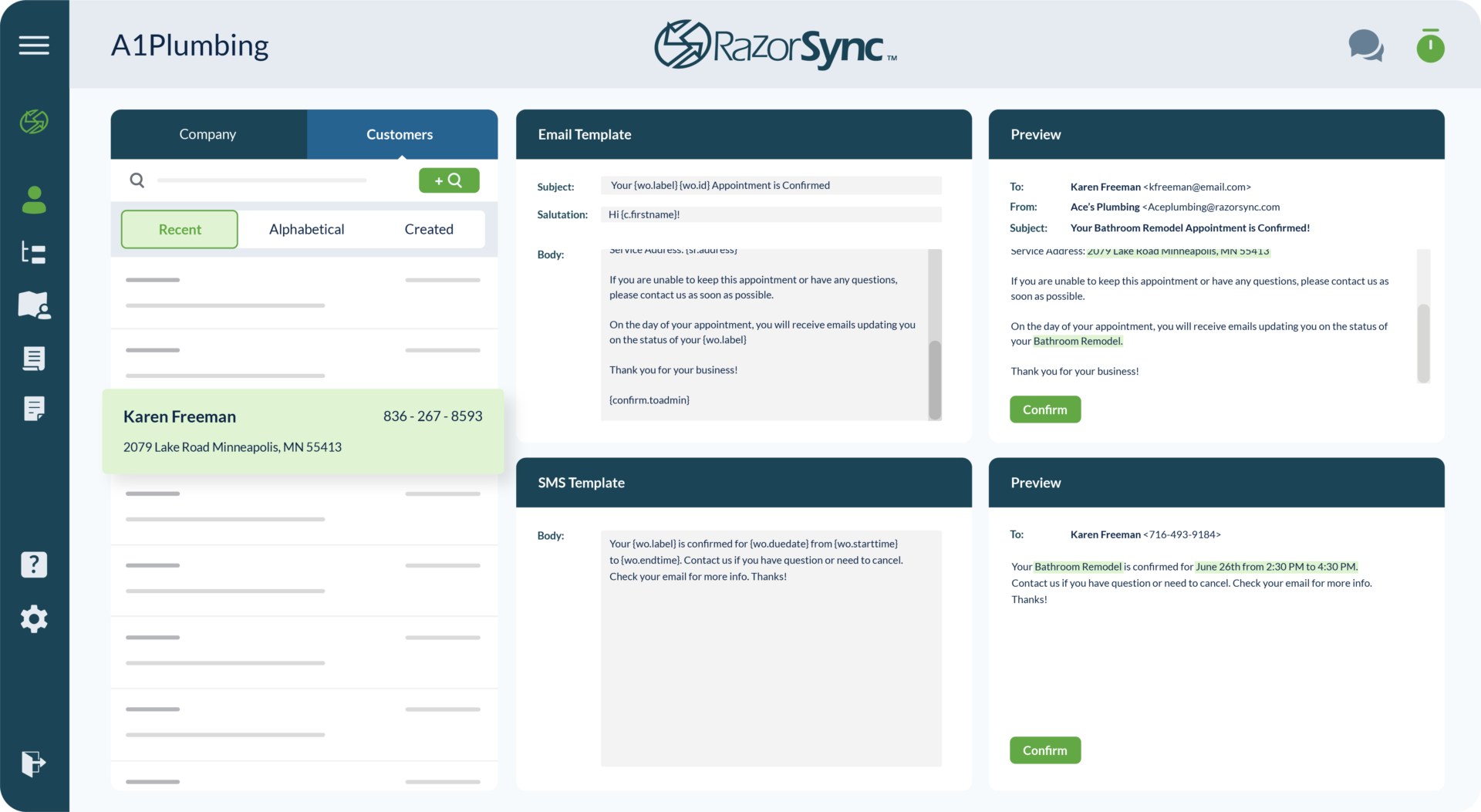

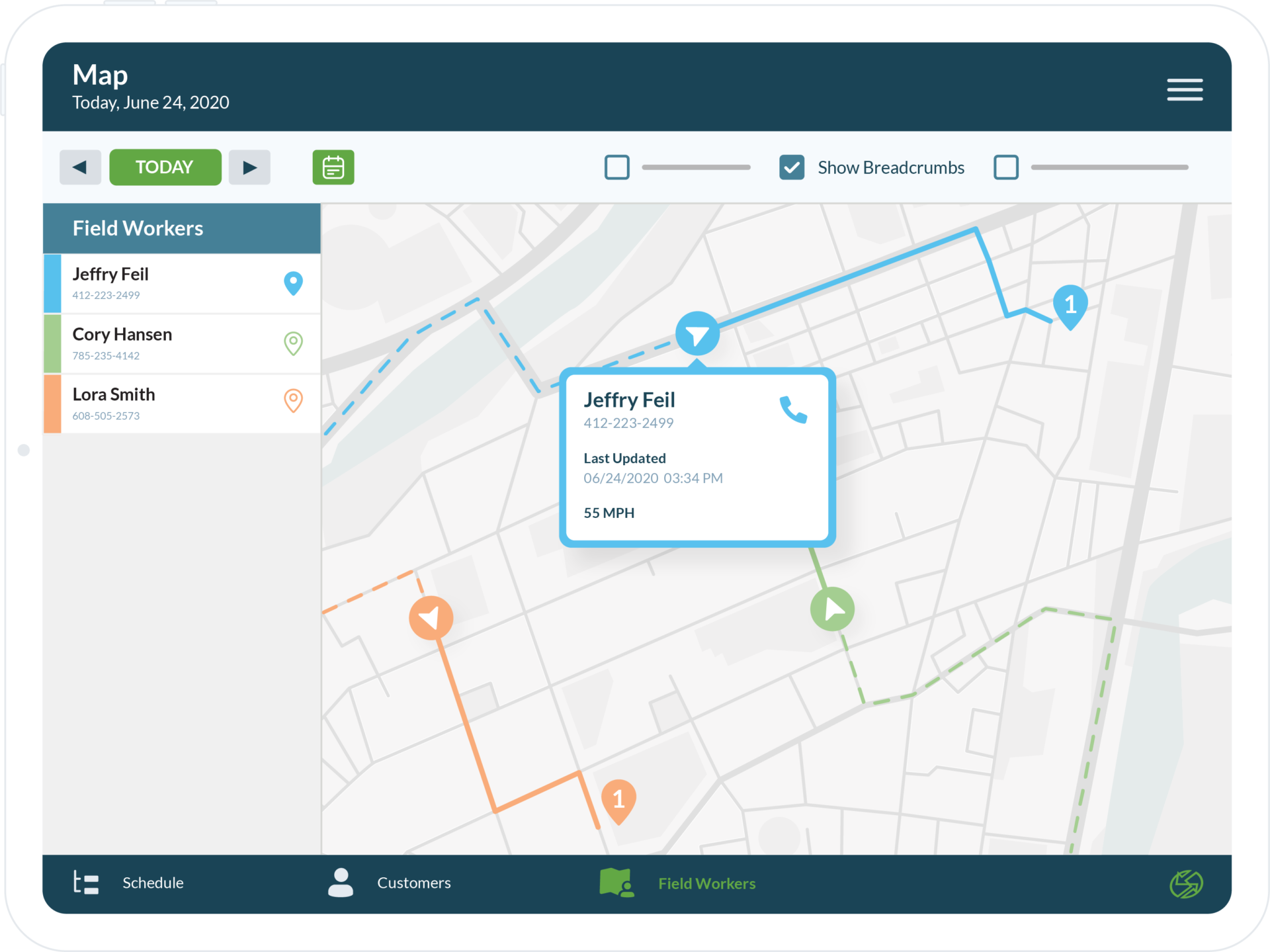

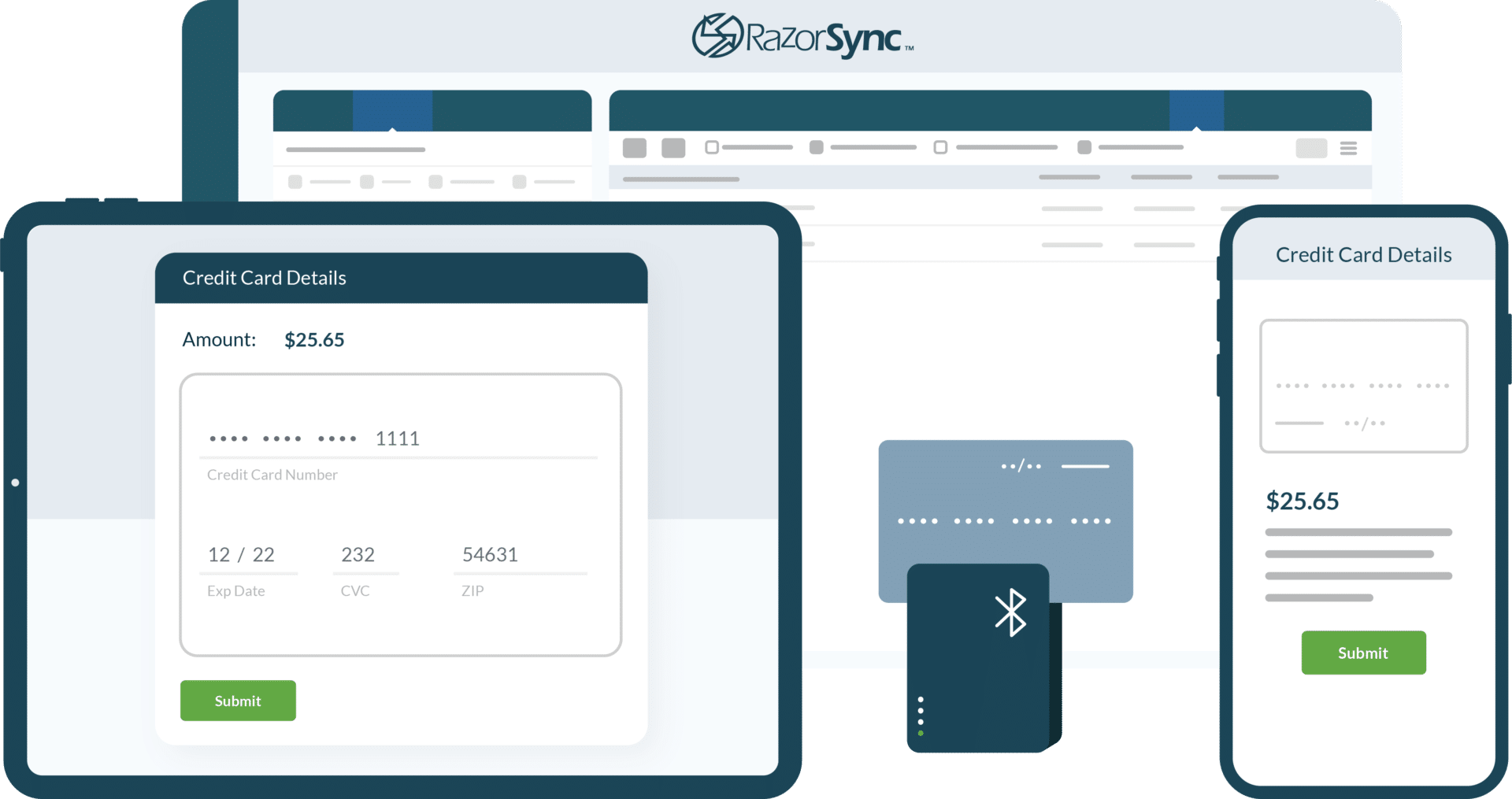

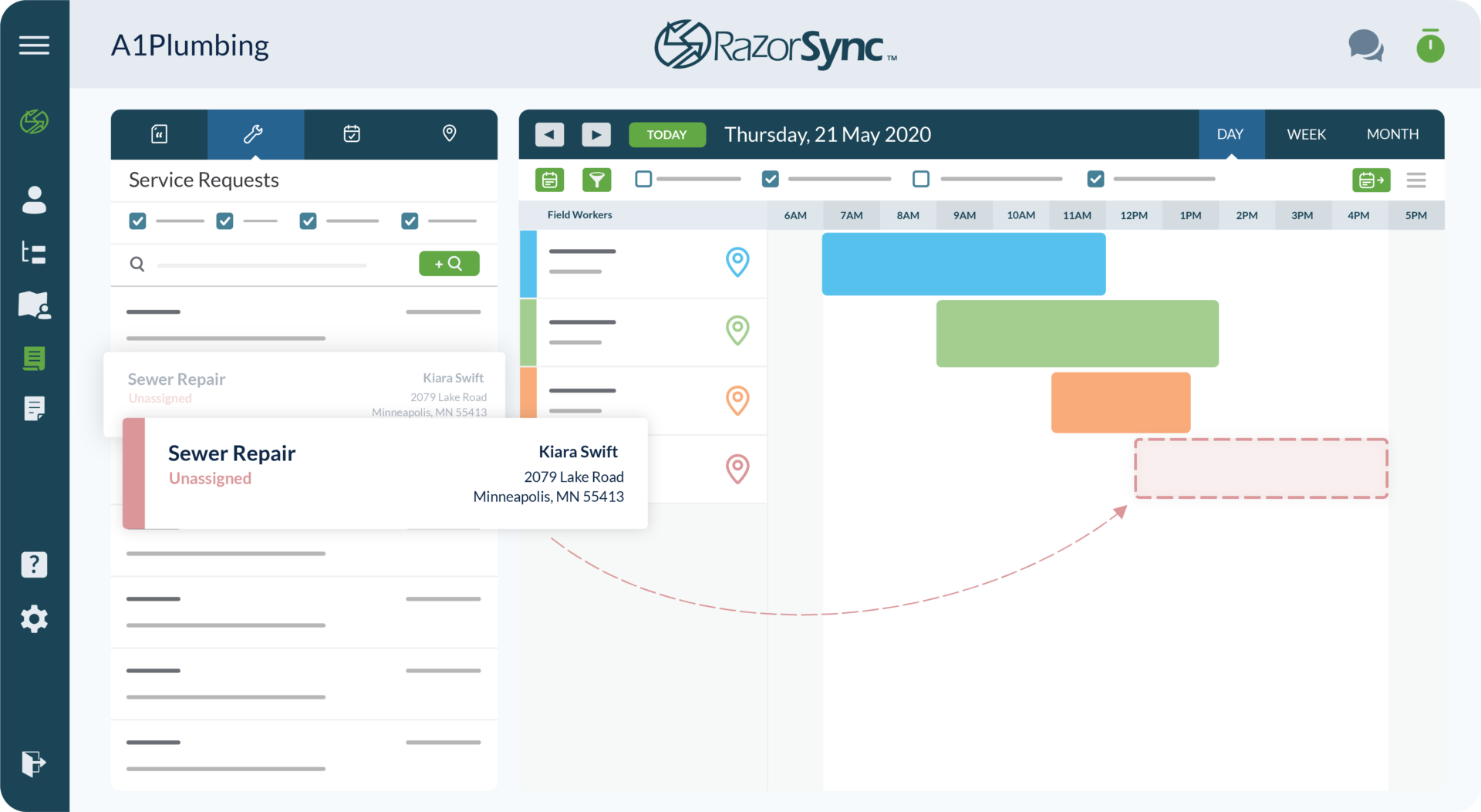

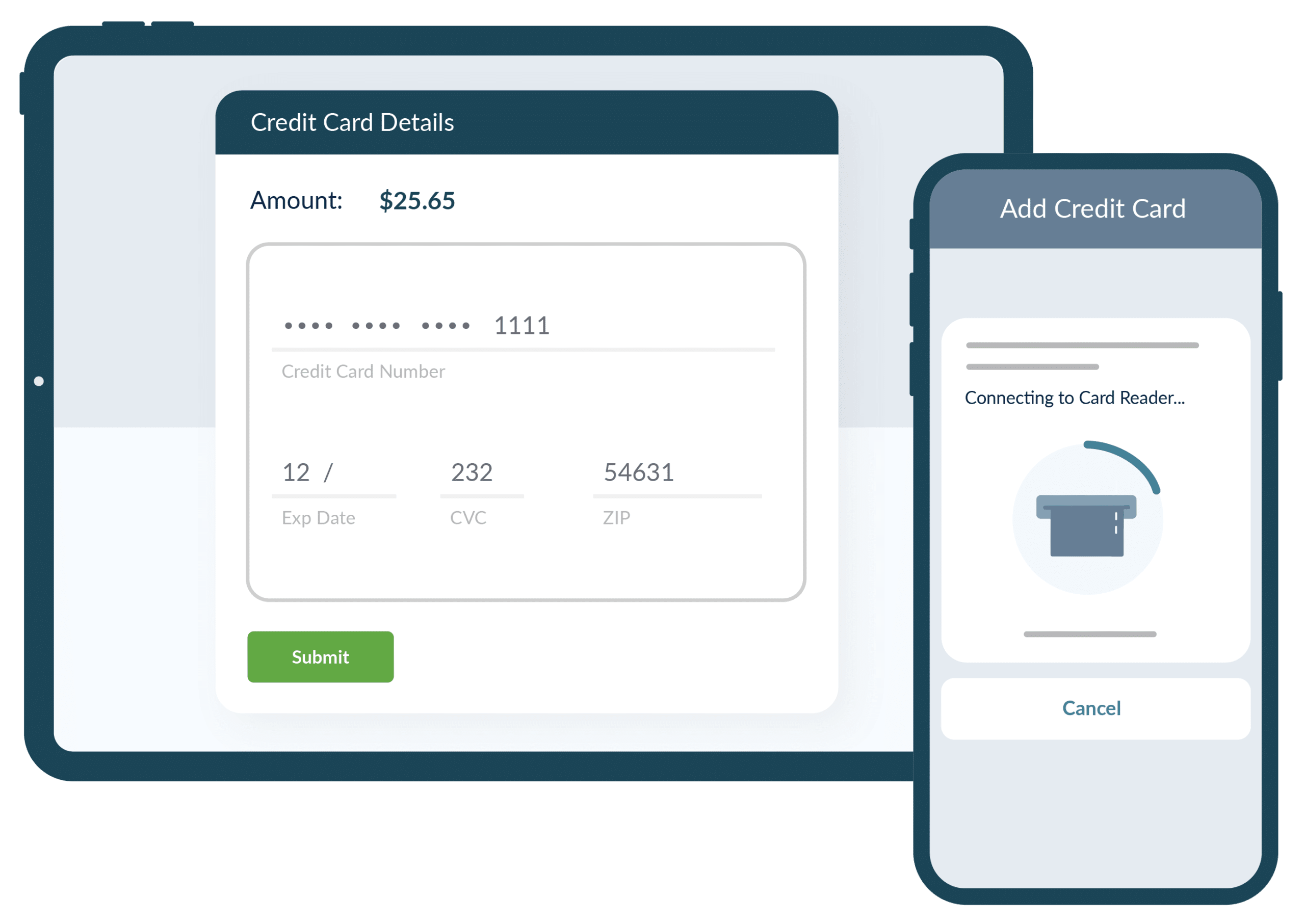

Making sure your team is up-to-date with the latest electrical safety standards can be hard in busier times, but it’s extremely important. With safety in mind and a powerful mobile field service software, your technicians will have the tools they need to work smarter and safer.